Toyooka City in Hyogo Prefecture boasts the largest production of bags in Japan.

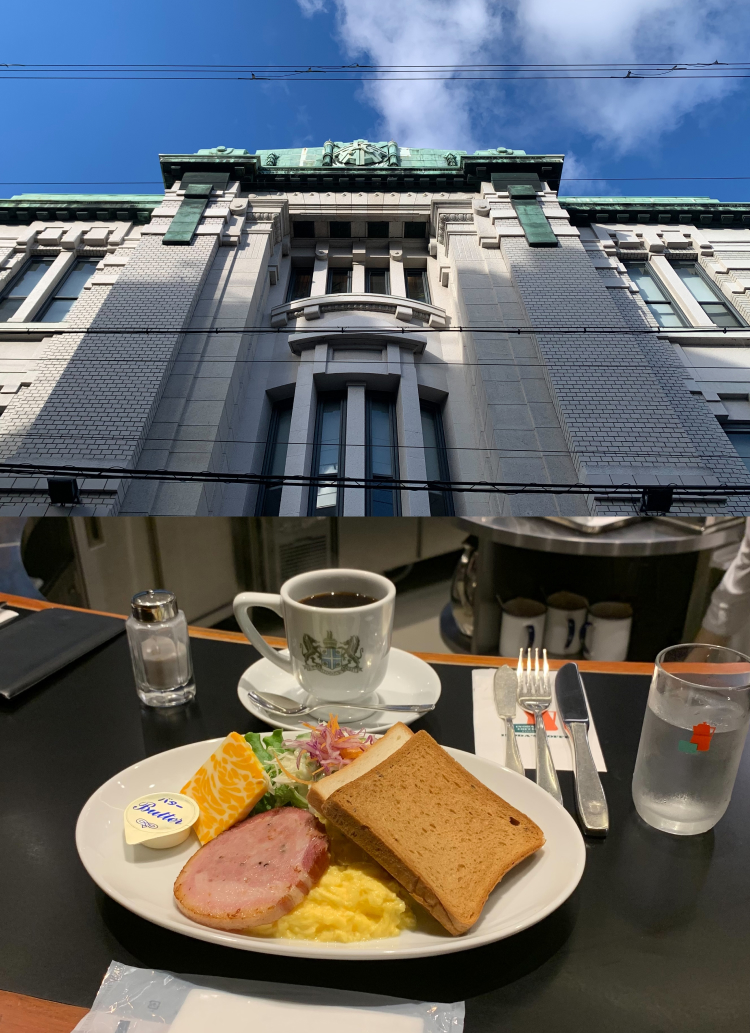

Toyooka City, Hyogo Prefecture. The city boasts the largest production of bags in Japan and is known as a mecca for bag makers with many factories in the city. Originally, the city flourished for about 1,200 years as a production center for box-shaped containers made of woven willow and bamboo called "yanagi-gori," and as time went by, the city began to produce bags.

Toyooka Bag is a local brand in Toyooka City that incorporates the technology cultivated over its long history. It is this brand that BELF BAGGAGE has collaborated with this time. The bags can only be made at factories certified by the association, and strict criteria are set in the screening process. The factory that produces the bags is "Masaaki Kiwada Shoten," one of the leading factories in the city. The in-line items of "BELF BAGGAGE" are also made at this factory. What made designer Kenta Sano fall in love with this factory? Let's find out why based on four keywords.

Born in Saitama, Japan in 1980, he launched "Beruf Baggage" in 2006 as his own designer. Since bicycles are at the center of his lifestyle, he started out with messenger bags, but now designs a variety of bags without changing his original "bicycle-inspired" background.

KEYWORD 01: Integrated Production

Unparalleled "integrated production

Quality.

Compared to other factories in Toyooka, Masaaki Kiwada Shoten has an overwhelmingly large site. There are many different types of equipment and craftsmen who operate them. According to Mr. Sano, the reason for this is because "the mainstream of bag making is based on the division of labor, whereas here we carry out integrated production from start to finish.

The quality of our products is overwhelmingly different when everything is completed in a single factory, from fabric cutting to parts processing, sewing, and inspection. If each process is entrusted to a specialized factory, quality will inevitably be uneven. It is also more difficult to control the delivery date. Craftsmen all share the common understanding that they want to make good bags, and by flexibly sharing this understanding within a single factory, stable quality can be achieved.