The bag brand started in 2015.UNBEND PRODUCTS〉. Based on classically shaped bags, these simple bags feature only the necessary functions, using high-tech materials such as yacht sails and "X-PAC," a waterproof and abrasion-resistant fabric.

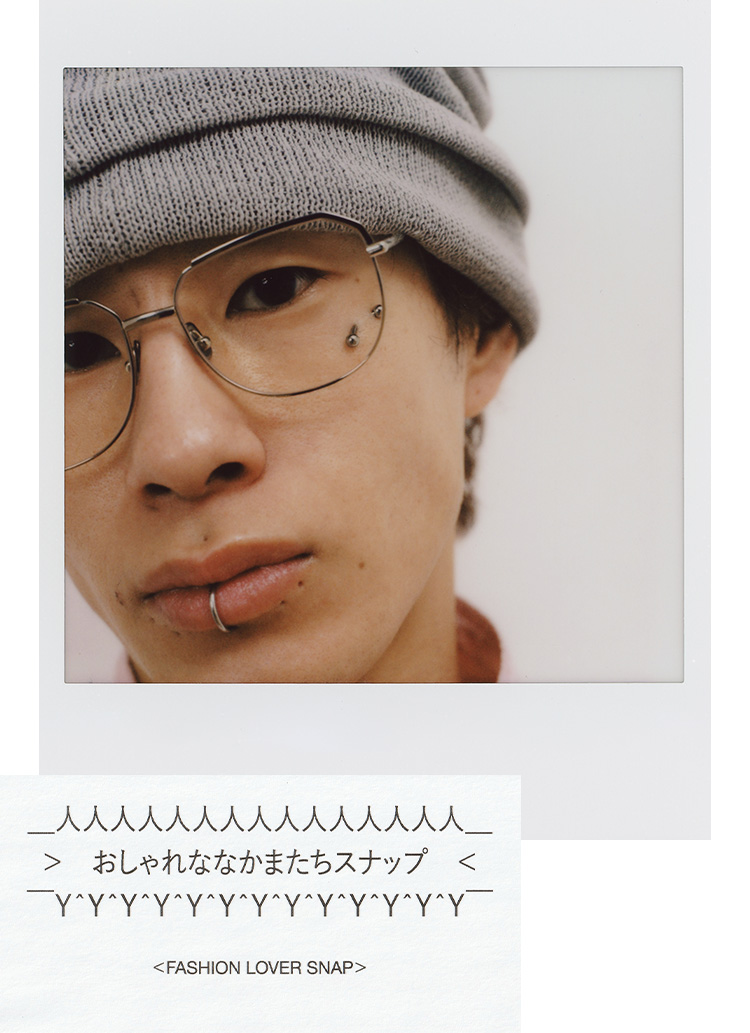

We interviewed Mr. Keita Nakayama, a designer who has been planning and producing bags for a bicycle shop while continuing to make handmade products under his own brand "Unbend Products" in his home and studio.

I like to look at the bags themselves, from vintage to current models. I like to look at the bags themselves, both vintage and current models," he says. They have a lot of pockets, strings coming out of them, etc. Some of them have unknown uses or reasons. Some of them have unknown purposes or reasons. It's fun to investigate and imagine the reasons.

This is a vintage daypack that I finally found last year after many years of searching. It was made by the bicycle manufacturer Cannondale in the early 1980s. It has an unusual plastic core inside.

Mr. Nakayama's interest in bags was sparked by an encounter with a daypack he bought for the first time in Tokyo when he was in junior high school.

I don't remember where I bought it, but I really liked and used a black nylon bag with a suede bottom from JAN SPORTS. It wasn't because it was popular at the time or because a skater I liked was carrying it, but because I was genuinely attracted to the nylon and suede material and shape.

He quit his previous job as a pattern maker for an apparel brand and started making things by hand, which led him to his current job.

When I went shopping at the store where I work as a customer, the president approached me and told me that he had made the backpack he wears, and he asked me if I wanted to join him. He asked me to join him. I found my next job on the spot (laughs). I was very lucky.

A Mitsubishi sewing machine made in the 80's that he searched for over a year. He had his favorite sewing machine from the 80's, which he got from his favorite sewing machine shop.

At first, I didn't know anything about bag fabrics and thought I could sew with a clothes sewing machine, but I couldn't sew at all. Unlike clothes, the fabric is so thick that the sewing machine needle would break. I made a lot of mistakes, but it was fun to find out for myself what I didn't know.

While gaining experience in bag making at his current workplace, Taro Uchiyama, the designer of "Ends and Means," whom he had known for a long time, gave him the opportunity to start his own brand, he says.

Taro-san also likes bags very much and is very particular about materials and details. Whenever we meet, we talk about materials and shapes. One day, he said to me, 'I want to use something you made. Make items that you really want to make now, without being bound by anything! I decided to start my own brand. The first product of "Unbend Products" was a backpack made in collaboration with "Ends and Means," but it was not a simple bag; I made an elaborate bag. I don't think a small brand would make a bag like a backpack, which requires a lot of work, for their first product. But at the time, the item I wanted to make was a backpack, and at the same time, I thought it would be a good way to create persuasiveness and enthusiasm as a brand.

MISSION PACK" is the first backpack created by Unbend Products. It is designed for a 3-day/2-night trip under the theme of "light trip. It is available in two colors, Black and Coyote. Currently, there are no production plans. 43,200 yen + tax

Unbend Products" designs classic shapes with high-tech materials. Each of the brand's items has its own concept.

I used X-PAC, which is waterproof and abrasion-resistant. I thought it was silly to use such an expensive material for just a bag. I thought it would be a message to the current industry and end-users that it was foolish, wasteful, and consumptive. I think it would be interesting to simply use functional fabrics and incorporate them into casual, easy-to-use items. But we also make products in fabrics that are not so functional, and we have Cordura nylon, which is a standard bag material. Why this fabric in a line of high-tech materials? or "Why are we releasing different materials at the same time? I think it would be interesting to have people think, "Why is this fabric used in a line of high-tech materials?

Top: "BUMP PACK-WHITE" made of yacht sail fabric. It is lightweight and tear-resistant. The fabric has a crisp texture and transparency. 8,100+TAX, Bottom: "BUMP PACK-COYOTE" made of X-PAC. ¥8,800+TAX

DSH BAG COYOTE" is made from a pouch that was actually used by the military, and the material was changed to "X-PAC". It is available in Black and Coyote, as well as Navy using a different fabric. 7,580 yen + tax

Regarding the origin of the brand name "Unbend Products," he said, "Bent wire is not perfectly straight, and inevitably becomes a snarky straight. It might be straightened by using a machine. But the snoring is the proof that human hands have worked on it, and that's what I love about it," says Nakayama.

We are conscious of giving our products a somewhat unpolished or handmade feel, not in the sense of being crude, but in the stitching and detailed handwork. We don't just look for materials at fabric stores, but sometimes find materials from places that have nothing to do with fashion, such as construction materials or medical materials. The shapes may look simple and ordinary, but there is something strange about them. I hope to create bags that have a "hook" that will remain in your memory once you see them.

Photo_Taro Hirayama

Edit&Text_Masato Saita

UNBEND PRODUCTS

www.unbend-products.com

INSTAGRAM:unbend_products