ヒップなファッション、カルチャー、ライフスタイルWEBマガジン

日本で初めてデニム生地の紡績から染色、織布、整理加工までの一貫生産を実現した「カイハラ」では、海外の生産者からデニム生地に最適な原綿を直輸入し、独自のノウハウで混綿、そして、原糸を自社製造することで、高い品質とローコストを両立させている。

At Kaihara, the first company in Japan to realize integrated production from denim fabric spinning through dyeing, weaving, and final processing, the finest raw cotton for denim is directly imported from manufacturers overseas. The raw cotton is blended using our trademark know-how, and by producing the thread for weaving ourselves, we are able to strike a balance between high quality and low cost.

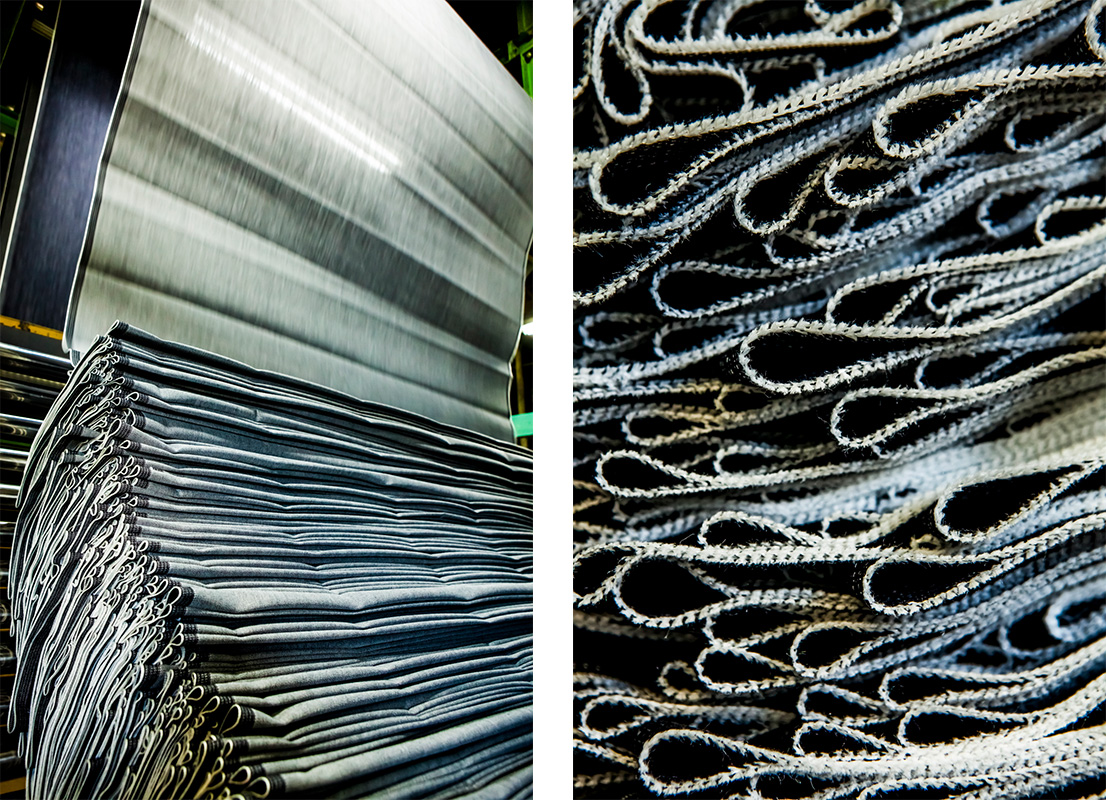

“一貫生産の確立” を目指して1991年に建てられたのが、この紡績工場。求める糸質によって、リング紡績とオープンエンド紡績の2つのラインを使い分ける。常に安定した品質を担保すべく、工場内はすべてオートメーション化されている。

This spinning mill was built in 1991 with the aim of establishing integrated production. The two lines – ring spinning and open-end spinning – are used for different purposes according to the desired thread quality. The entire factory is automated in order to ensure consistent, stable quality.

“1893年の創業以来、備後絣の藍染で培ってきた「カイハラ」の経験と技術力は、他の追随を許さない。ロープ状に束ねられた原糸をインディゴ液に通し、ローラーで絞り、空気に触れて酸化させる…。このプロセスを何度も繰り返すことで、特有の鮮やかなインディゴブルーが出来上がる。糸の芯部は白く残るため、ジーンズの洗い加工後のヴィンテージ感が実現できるというわけだ。

Ever since its founding in 1893, Kaihara’s experience and technical ability – fostered through bingo-gasuri indigo dyeing – have been unsurpassed. The thread for weaving is tied up like rope and put through indigo liquid, pressed with a roller, and oxidized by being exposed to air. This process is repeated numerous times, lending the thread a characteristically vivid indigo blue. The core of the thread remains white, which is why the jeans have a vintage feel after wash processing.

日本を象徴するものでありながら、戦時中は栽培が禁止された藍。「カイハラ」は、その高い藍染技術こそがカイハラデニムのクオリティを定義するという考えのもと、最新鋭のテクノロジーを精力的に取り入れながら、伝統技術の未来への橋渡し役も担っている。

Although indigo is a symbol of Japan, its cultivation was banned during wartime. Based on the belief that our high-level indigo dye techniques are what define the quality of Kaihara denim, Kaihara vigorously adopts the latest technology while also taking on a role in ensuring that traditional techniques thrive in the future.

糊付けされたタテ糸にヨコ糸を打ち込み、布に織り上げる工程である「織布」。「カイハラ」の工場では、ヘビーウエイトなデニムに対応するプロジェクタイル織機、細番手のデニムに用いられるレピア織機、そして、〈ラグ & ボーン〉も採用しているクラシックなテイストのヴィンテージデニムを織り上げるシャトル織機など、300台以上もの織機が常に稼動している。

Fabric weaving is the process wherein weft yarn is interlaced with starched warp yarn, and woven into fabric. At the Kaihara factory, we have over 300 looms in constant operation, including projectile looms for heavyweight denim, rapier looms used for denim made of fine thread, and classic shuttle looms for weaving vintage denim, which are also used by rag & bone.

たとえアートのように美しいデニム生地でも、品質にバラツキがあってはいけない。中間検査を終えた原反は、表面のケバを取る毛焼き、生地にコシを持たせる糊付け、ヨジレを防ぐ斜行防止、縮みを防ぐ防縮加工や乾燥処理などを経てようやく、最終的な製品となる。こうした丁寧なプロセスが、独特の風合いとニュアンスを与えているのだ。

Even if you have beautiful, artlike denim fabric, it is no use if the quality is scattershot. Original fabric that has completed an interim inspection is singed to remove the fluff from the surface, starched to give the fabric body, given skew prevention to protect against distortion, pre-shrunk to prevent shrinkage and dry processed before finally completing its journey to become a product. This careful process is what gives Kaihara denim its characteristic texture and nuance.

「カイハラのセルビッジデニムに代わるものは、世界のどこを探しても見つけられない。彼らにしか実現できないアートなんだ」。マーカス・ウェインライトを〈ラグ & ボーン〉設立へと導いたきっかけのひとつであり、“オーセンティシティ” というブランド哲学の確立の道標となったのが、彼が初めて自身のためのジーンズづくりに勤しんだアメリカ・ケンタッキー州の工場で出会った、カイハラデニムだ。

「カイハラ」のセルビッジデニムは、〈ラグ & ボーン〉のみならず、“クオリティ” をスローガンに掲げる世界の錚々たるブランドのデニムづくりに、もはや不可避な存在だ。その唯一性は、ひとたびカイハラデニムを体験した人であれば、誰もが認めるところだが、これほどのグローバルな評価と信頼、そして比肩なきブランド力を支えているのは、正藍染の絣製造からはじまった創業120余年の老舗企業の、ひたむきな努力と革新性にほかならない。

「カイハラ」の営業部課長を務める藤野光輝さんは、こう語る。

「藍(インディゴ)は、『ジャパンブルー』とも呼ばれる通り、昔から日本人の生活、民芸に欠かせない重要な染料である一方、コントロールが非常に難しい。我々は、創業以来培ってきた高度な藍染技術によって、世界でもっとも安定した色を出すことができる自負がありますし、ヴィンテージのジーンズに近い絶妙な色出しを実現すべく、工夫を重ねてきました。計算されたムラ糸と織機設定のバランス…。我々にしか出せない風合いが、こうして多くの人に支持されているのだと思います」

事実、マーカスはカイハラの藍色に “恋に落ちた” ひとりである。

「インディゴはマジカルな染料であり、デニムもまた、マジカルな生地。この二つがカイハラの技術によって交わることで、ほかでは到底叶えられない “着るごとにどんどんよくなる独自の風合い” を実現している。奇跡のファブリックだよ」

カイハラにとっても、デニムは倒産から自社を救った運命の生地だ。社会や生活様式の変化から、それまで生業にしてきたコットンやウールの絣製造に陰りが見えた頃、当時の若者や学生たちのあいだで流行し始めていたジーンズ、つまり、彼らにとって新しい藍染の素材、デニム地に、いちやはく目をつけたのだった。

“温故創新” をスローガンに、変化を恐れず挑戦をやめない「カイハラ」は、これからの未来をどう見つめているのだろう。前出の藤野さんは、同社の展望をこう話してくれた。

「品質や開発力はもちろん、究極的には、デニムの販売量においても世界No.1を目指します。自社ブランドのジーンズ製品の製造販売も、いつか実現したい。さらには、先代がデニムに出会って『カイハラ』を飛躍させたように、わたしたちも、新しい藍染の生地づくりに挑戦していきたいと考えています」

“Something better than Kaihara’s selvedge denim? Even if you search all over the world, you’re never going to find it. It’s an artform only they are capable of creating.”One of the motivating factors that led Marcus to founding rag & bone – a guidepost for establishing his brand’s philosophy of “authenticity” – was something he encountered in the Kentucky factory where he first endeavored to make jeans for himself: Kaihara denim.

Aside from rag & bone, Kaihara’s selvedge denim is now an indispensable part of denim production for the world’s foremost brands that put “quality” in their slogans. The uniqueness is noticeable by anyone who has tried Kaihara denim even once, but the true reasons for such global recognition and trust, as well as Kaihara’s incomparable brand strength, are none other than the single-minded effort and innovation of this well-established company, which started over 120 years ago making authentic indigo-dyed kasuri fabric.

Koki Fujino, section chief in Kaihara’s sales department, has this to say :

“Indigo, or as its other name ‘Japan blue’ suggests, has been an essential dye in the lives and folk art of Japanese since the olden days, but it is extremely difficult to control. Using the high-level indigo dye techniques that have been cultivated since our founding, we are confident in our ability to bring out the world’s most balanced colors, and have devised better ways to realize the perfect blanching that brings [our denim] closer to vintage jeans. The balance of the calculatedly uneven thread with the loom’s settings… The textures only we can create are, I believe, made possible by a great number of people.”

Marcus is truly someone who has “fallen in love” with Kaihara’s indigo blue.

“Indigo is a magical dye, and denim, too, a magical fabric. By bringing these two together through Kaihara’s techniques, a ‘unique texture that gets better and better every time you wear it,’ something no one else can possibly achieve, has been realized. It’s truly a miracle fabric.”

For Kaihara, too, denim is the fated fabric that rescued the company from bankruptcy. At one point, changes in society and lifestyles cast a visible shadow over kasuri fabrics that were made with cotton and wool, which had until then been the company’s bread and butter. Around this time, a new fad that had started among young people and students was jeans: in other words, a different raw material for those at Kaihara to apply indigo dye to. They quickly set their sights on denim fabric.

Taking as its slogan, “Creating the future with the past,” Kaihara has continued to challenge itself, undaunted by change. What does the future hold? Mr. Fujino, quoted above, spoke to us about the company’s prospects.

“Besides simply quality and ingenuity, ultimately we are also aiming to be number one in the world in terms of denim sales volume. Someday, we also hope to manufacture and sell our own brand of jeans. Furthermore, just as our predecessors took Kaihara to great heights after encountering denim, we too are hoping to try and create a new fabric ideal for indigo dyeing.”