HOUYHNHNM: Hip fashion, culture and lifestyle web magazine

KAIHARA, the first company in Japan to achieve integrated production of denim fabrics from spinning, dyeing, weaving, and finishing, imports directly from overseas producers the most suitable raw cotton for denim fabrics, blends it with its own know-how, and produces the raw yarn in-house, thereby achieving both high quality and low cost.

At Kaihara, the first company in Japan to realize integrated production from denim fabric spinning through dyeing, weaving, and final processing, the finest raw cotton for denim is directly imported from manufacturers overseas. The raw cotton is blended using our trademark know-how, and by producing the thread for weaving ourselves, we are able to strike a balance between high quality and quality. The raw cotton is blended using our trademark know-how, and by producing the thread for weaving ourselves, we are able to strike a balance between high quality and low cost.

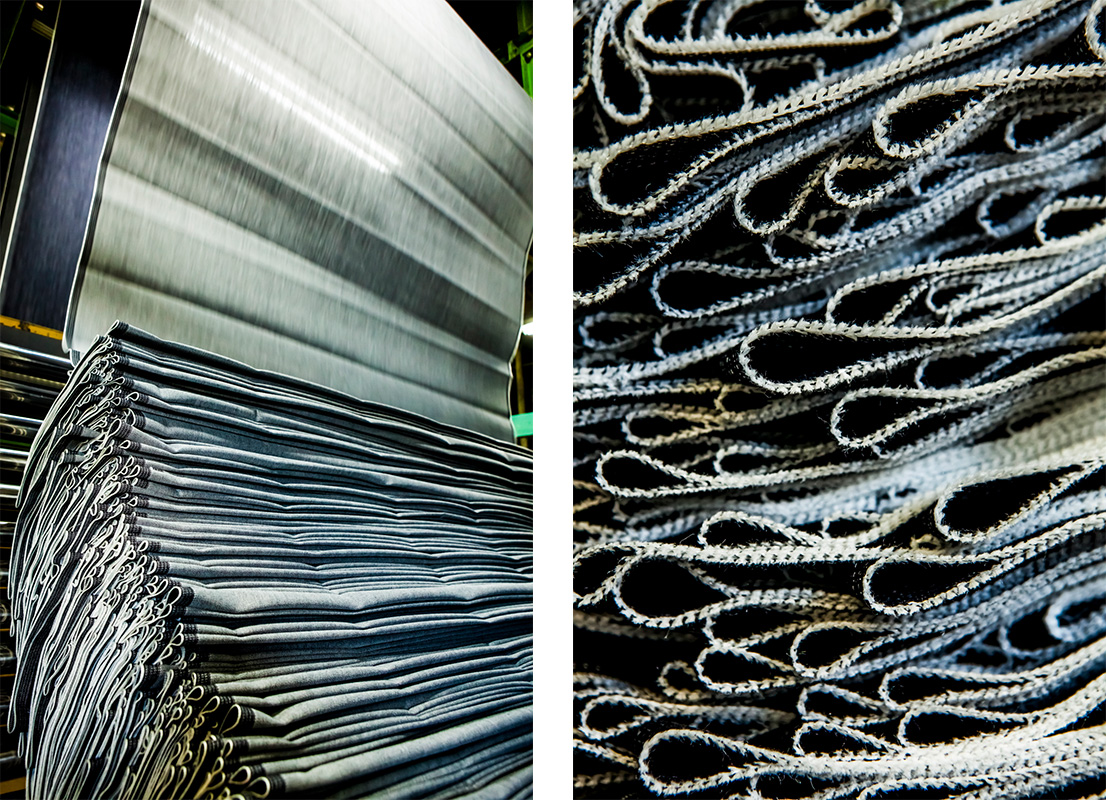

This spinning mill was built in 1991 with the aim of "establishing integrated production. Two spinning lines, ring spinning and open-ended spinning, are used according to the quality of yarn required. The entire factory is automated to ensure consistent quality at all times.

This spinning mill was built in 1991 with the aim of establishing integrated production. The two lines - ring spinning and open-end spinning - The entire factory is automated in order to ensure consistent, stable quality. The entire factory is automated in order to ensure consistent, stable quality.

"KAIHARA's experience and technical capabilities, cultivated through indigo dyeing of Bingo Kasuri since its establishment in 1893, are unrivaled. Rope-like strands of raw silk are passed through an indigo solution, squeezed with rollers, and exposed to air to oxidize.... This process is repeated many times to produce the unique bright indigo blue color. The core of the yarn remains white, giving the jeans a washed-out, vintage look.

Ever since its founding in 1893, Kaihara's experience and technical ability - fostered through bingo-gasuri indigo dyeing - have been unsurpassed. - The thread for weaving is tied up like rope and put through indigo liquid, pressed with a roller, and oxidized by being exposed to air. This process is repeated numerous times, lending the thread a characteristically vivid indigo blue. white, which is why the jeans have a vintage feel after wash processing.

Indigo is a symbol of Japan, but its cultivation was banned during the war. Kaihara" believes that the high level of indigo-dyeing technology defines the quality of Kaihara denim, and while vigorously introducing cutting-edge technology, the company also serves as a bridge to the future of traditional techniques.

Although indigo is a symbol of Japan, its cultivation was banned during wartime. Based on the belief that our high-level indigo dye techniques are what define the quality of Kaihara denim, Kaihara vigorously adopts the latest technology while also taking on a role in ensuring that traditional techniques Based on the belief our high-level indigo dye techniques what define the quality of Kaihara denim, Kaihara vigorously adopts the latest technology while also taking on a role in ensuring that traditional techniques thrive in the future.

Weaving is the process of beating the weft into the glued warp threads and weaving them into cloth. At the KAIHARA factory, more than 300 looms are in constant operation, including projectile looms for heavyweight denim, rapier looms for fine denim, and shuttle looms for weaving vintage denim with a classic taste, which Rag & Bone also uses. Rag & Bone also uses shuttle looms to weave vintage denim with a classic taste.

Fabric weaving is the process wherein weft yarn is interlaced with starched warp yarn, and woven into fabric. At the Kaihara factory, we have over 300 looms in constant operation, including projectile looms for heavyweight denim, rapier looms used for denim made of fine thread, and classic shuttle looms for weaving vintage denim, which are At the Kaihara factory we have over 300 looms in constant operation, including projectile looms for heavyweight denim, rapier looms used for denim made of fine thread, and classic shuttle looms for weaving vintage denim, which are also used by rag & bone.

Even if the denim fabric is as beautiful as art, there must be no variation in quality. After completing intermediate inspections, the raw fabric undergoes a process that includes hair burning to remove surface fluff, gluing to give the fabric firmness, anti-straightening to prevent sagging, shrink-proofing and drying to prevent shrinkage, and finally becoming the final product. This careful process gives the fabric its unique texture and nuance.

Even if you have beautiful, artlike denim fabric, it is no use if the quality is scattershot. Original fabric that has completed an interim inspection is Original fabric that has completed an interim inspection is singed to remove the fluff from the surface, starched to give the fabric body, given skew prevention to protect against distortion, pre-shrunk to prevent This careful process is what gives Kaihara denim its This careful process is what gives Kaihara denim its characteristic texture and nuance.

Kaihara's selvedge denim can't be found anywhere else in the world. It's an art that only they can realize. One of the factors that led Marcus Wainwright to establish Rag & Bone, and the guiding light for the brand's philosophy of "authenticity," was a pair of Kaihara denim jeans he first encountered at a factory in Kentucky, USA, where he was making jeans for himself. He first encountered Kaihara denim at a factory in Kentucky, U.S.A., where he worked on making jeans for himself.

Kaihara's selvedge denim has become an inescapable part of denim production not only for Rag & Bone, but also for many of the world's most prestigious denim brands, which have "quality" as their slogan. The uniqueness of Kaihara denim is recognized by anyone who has experienced it, and the reason for its global reputation, trust, and unparalleled brand power is nothing but the earnest efforts and innovation of this 120-year-old company that began as a manufacturer of indigo-dyed kasuri fabrics.

Mitsuteru Fujino, section manager of the sales department at Kaihara, said, "We are very pleased with the quality of our products.

Indigo, also known as "Japan blue," has long been an important dye essential to Japanese life and folk art, but it is also extremely difficult to control. We take pride in our ability to produce the most stable color in the world with the advanced indigo dyeing technology we have cultivated since our establishment, and we have worked hard to achieve an exquisite coloring similar to that of vintage jeans. We have also worked hard to achieve a balance between the calculated uneven yarns and loom settings. I believe that the texture that only we can produce is the reason why so many people support our products.

In fact, Marcus is one of those who "fell in love" with the indigo of Cajara.

Indigo is a magical dye, and denim is also a magical fabric. By combining these two through Kaihara's technology, we have achieved a unique texture that gets better and better with each wear, which cannot be achieved by any other fabric. It is a miracle fabric.

For KAIHARA, denim was the fabric that saved the company from bankruptcy. When changes in society and lifestyles had put a damper on the cotton and wool kasuri manufacturing that had been the company's livelihood, Kaihara turned to jeans, a new indigo-dyed material that was becoming popular among the youth and students of the time, and thus denim fabric.

Under the slogan of "Innovation from the past," KAIHARA is not afraid of change and will never stop challenging itself. Mr. Fujino, mentioned above, gave us his outlook on the company's future.

We aim to become No. 1 in the world in denim sales volume, not to mention quality and development capabilities," he said. We would like to manufacture and sell our own brand of jeans someday. Furthermore, just as our predecessors made a great leap forward with denim, we would like to take on the challenge of creating new indigo-dyed fabrics.

"Something better than Kaihara's selvedge denim? Even if you search all over the world, you're never going to find it. It's an artform only they are capable of creating. "One of the motivating factors that led Marcus to founding rag & bone - One of the motivating factors that led Marcus to founding rag & bone One of the motivating factors that led Marcus to founding rag & bone a guidepost for establishing his brand's philosophy of "authenticity" - was something he encountered in the Kentucky factory where he first endeavored to make jeans for himself: Kaihara denim.

Aside from rag & bone, Kaihara's selvedge denim is now an indispensable part of denim production for the world's foremost brands that put "quality" in their slogans. The uniqueness is noticeable by anyone who has tried Kaihara denim even once, but the true reasons for such global recognition and trust, as well as the ability to create a unique denim that is truly unique. The uniqueness is noticeable by anyone who has tried Kaihara denim even once, but the true reasons for such global recognition and trust, as well as Kaihara's incomparable brand strength, are none other than the single- minded effort and innovation of this well-rounded brand. minded effort and innovation of this well-established company, which started over 120 years ago making authentic indigo-dyed kasuri fabric.

Koki Fujino, section chief in Kaihara's sales department, has this to say : : Kaihara's sales department has been working with Kaihara's sales team for over 20 years.

"Indigo, or as its other name 'Japan blue' suggests, has been an essential dye in the lives and folk art of Using the high-level indigo dye techniques that have been cultivated since our Using the high-level indigo dye techniques that have been cultivated since our founding, we are confident in our ability to bring out the world's most balanced colors, and have devised better ways to realize the perfect The balance of the calculatedly uneven thread with the loom's settings ... The textures only we can create are, I believe, made possible by a great number of people."

Marcus is truly someone who has "fallen in love" with Kaihara's indigo blue.

"Indigo is a magical dye, and denim, too, is a magical fabric. By bringing these two together through Kaihara's techniques, a By bringing these two together through Kaihara's techniques, a 'unique texture that gets better and better every time you wear it,' something no one else can possibly achieve, has been It's truly a miracle fabric."

For Kaihara, too, denim is the fated fabric that rescued the company from bankruptcy. At one point, changes in society and lifestyles cast a visible shadow over kasuri fabrics that were made with cotton and wool, which had until then been the company's bread and butter. Around this time, a new fad that had started among young people and students was jeans: in other words, a different raw material for those at Kaihara to apply indigo dye to. quickly set their sights on denim fabric.

Taking as its slogan, "Creating the future with the past," Kaihara has continued to challenge itself, undaunted by change. Mr. Fujino, quoted above, spoke to us about the company's prospects.

"Besides simply quality and ingenuity, ultimately we are also aiming to be number one in the world in terms of denim sales volume. Furthermore, just as our predecessors took Kaihara to great heights after encountering denim, we Furthermore, just as our predecessors took Kaihara to great heights after encountering denim, we too are hoping to try and create a new fabric ideal for indigo dyeing.