The best quality in the world, produced by technology and nature's bounty .

After the down is thoroughly cleaned of dirt and dust, it is placed in a huge drum-type washing machine. This "washing and recovery process" is the essence of Kawada Feathers, and is the reason why we can call our down the best quality down in the world!

If the feathers are left with stains such as reddish dirt or dust, they are more prone to go flat and develop odors, while clean feathers will keep their loft even after years of wear. They say that even if the same down is used, there is a big difference in quality depending on cleanliness.

Kawada Feathers uses a specially customized down washing machine for washing and restoring feathers. The unique technology of washing by rubbing feathers against each other like grinding rice, and the use of ultra-soft water with extremely strong reducing power, remove dirt without damaging the feathers. The degree of cleanliness, which indicates the cleanliness of the down, is about twice the industry standard. Using a special natural detergent made from coconut oil, the feathers are washed twice in hot water of approximately 45°C and rinsed four times.

And there is another reason why we are unrivaled. . it is in the land.

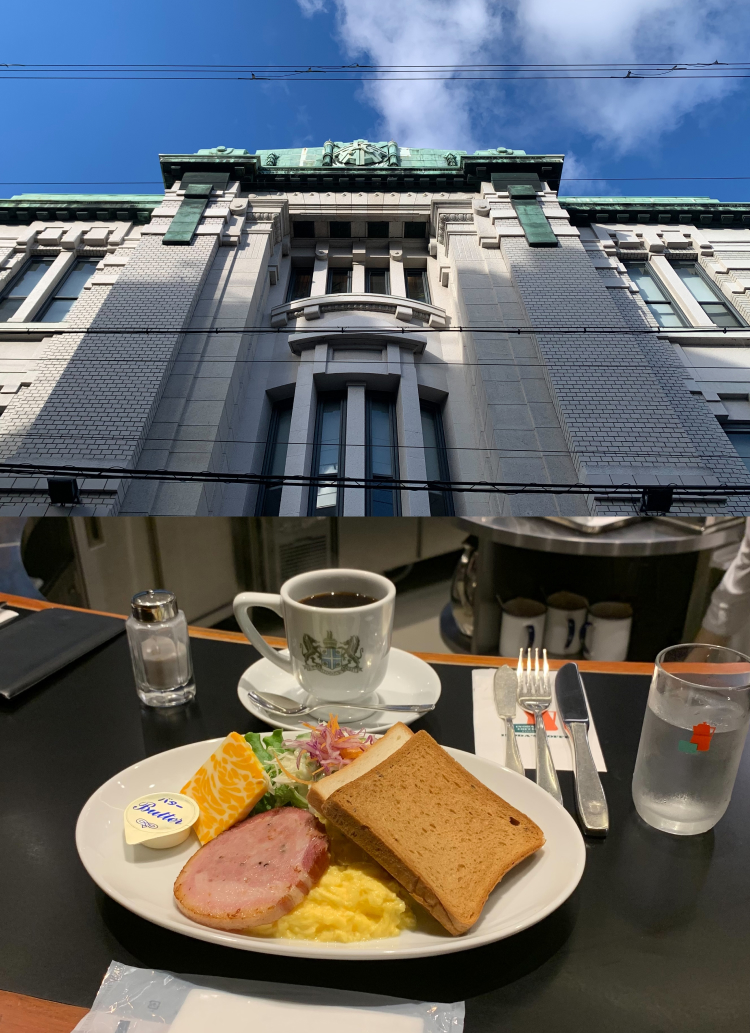

Toshikatsu Kawata, the current president, foresaw in the 1980s that the down industry would become globally competitive in the 2000s. In order to differentiate his company from others, he aimed to improve quality = establish better feather refining technology. Kawata, who understood the structure and characteristics of feathers and had designed the refining machinery, focused on the environment suitable for feather refining. Low humidity is better because high temperatures and high humidity prevent the down fibers, the small feathers, from opening and the dirt in the crevices from being completely removed. As for water, which is essential for cleaning, ultra-soft water with strong reducing power that penetrates into every nook and cranny of the feathers and repairs damaged feathers with its antioxidant power is preferable.

Based on these two points, Mr. Kawata proposed the site to the previous president in Meiwa-machi, Taki County, Mie Prefecture. In 1991, a new factory was built in Meiwa, and compared to the Nagoya factory, which was doing the same work, the improvement in quality due to the environment was obvious. They have succeeded in refining down that leaves almost no dirt. . Mr. Sato nods in agreement with the effects of the ultra-soft water.

The collar is also equipped with a fleece-tailored windshield to keep out the cold air.

It makes sense that a place with such clean water would produce such high quality products. The other day, I went to Wetzlar, Germany, where the headquarters factory of my favorite camera, Leica, is located, for an event. Clean water is necessary for the production of camera lenses, and Wetzlar is no exception. Also, a printing company in Nagano, Japan, which we often request prints from, told us that they were founded there because of the clean water. So clean water is the key word for a wide variety of products.

After the "cleaning and recovery process" is completed, the down is "dried" at once in a custom-built dryer. This dryer is heated to a high temperature of 150 ℃, and the short drying time reduces the load on the down due to heat, and also sterilizes and deodorizes the down. After that, steam is applied to the feathers to spread them out , and they are dried again. After the fluffy feathers have been produced and "cooled" to room temperature, they are "dusted" again. Here, the down is cleaned of dirt, dust, and protein powder derived from the feathers. As a side note, the protein powder removed in this process is reused as cosmetics and water repellent.

Kawada Feathers' slogan, "Down is tasteless and odorless," is posted throughout the factory. This slogan expresses President Kawada's belief that down that has been cleaned perfectly tastes and smells nothing. These words are typical of Kawada Feathers, which refines high-quality down through thorough cleaning and recovery processes.