EYEVAN was born in 1972 as the first fashion eyewear brand in Japan based on the concept of "glasses that can be worn. Over its long history, EYEVAN has been recognized for its quality and design, and has left behind an illustrious history, including a licensing agreement with Oliver Peoples of the U.S., as well as being the favorite of numerous celebrities.

10 eyevan," which was born from this brand in 2017, is a completely new approach to eyewear created under the concept of "beautiful tools. . What makes it unique are its parts. Designer Hirotaka Nakagawa has been involved in eyewear design for many years, and as a result of carefully updating his ideas one by one, 10 special parts were created. By using these parts, he was able to create eyewear that is different from what was previously available.

The glasses look simple, but what has changed? So what exactly has changed? We asked Mr. Nakagawa, the designer, to tell us.

PROFILE

He started his career in the machine tool industry and later entered the eyeglass industry. After 3 years of brand management, he joined Ivan Inc. as a designer.

Function and design created by reviewing the parts.

How did 10 Ivan get its start?

Nakagawa:I was originally in charge of designing the main collection called "Ivan 7285," but during the course of my work, I came up with parts that had never existed before, and the ideas kept accumulating.

You are referring to the 10 parts used in the "10 Ivan" items, aren't you?

An amazingly dainty and delicately designed item. Not to mention, it is also extremely lightweight.

Nakagawa:Yes. On the other hand, I also met skilled craftsmen in Sabae, Fukui. . In this way, we gradually created an environment in which we could realize the ideas we had in mind.

I see.

Nakagawa:For example, one symbolic element is a screw. The screws used in "10 Ivan" are called Torx screws, which are star-shaped screws used in iPhones and motorcycles.

What is the difference from ordinary screws?

Nakagawa: In the screw industry, this screw is famous for being easy to tighten and hard to loosen. This star-shaped screw hole fits the screwdriver and tightens with a little force. On the other hand, the spiral shaped gills are called OS lock, which is also a feature that makes it difficult to loosen. In fact, eyewear requires re-tightening every time a screw comes loose, but the number of times this is required is reduced by far.

Have there been no screws in the past?

Nakagawa: There was one, but it was made of stainless steel. The material we used this time is a strong material called beta titanium. The structure is so easy to tighten that even a slight force is enough to cause the head of the screw to fly off. The reason why these screws were not made in the past is simply that they are difficult to make. They are small in size and costly to make, and they probably didn't feel the need to go that far.

What are the other benefits besides fewer re-tightenings?

Nakagawa:One of the criteria for judging the quality of eyewear is a movement called "agaki," which is the smoothness of opening and closing the temples. This refers to the smoothness of opening and closing the temples, and the use of this screw makes the "agaki" movement very smooth. With normal screws, you may feel a tugging sensation or the metal rubbing against the temples, but this rubbing means that the screws tend to loosen easily and float. This can lead to an imbalance or a strange feeling of discomfort when the wearer wears it on the face. With "10 Ivan," we have solved this problem.

When the special screwdriver is inserted, there is a sense of the unevenness of the surface fitting tightly together. The shape is based on mechanical calculations.

Nakagawa: And there is another advantage. Because the Torx screws are easy to tighten and do not loosen easily, the length of the screw can be shorter than that of a regular screw. The screws are used in a part called the "head," which is the part connecting the front of the frame to the temples. The shorter the screws are, the less thickness can be used for the "wick" as well. In short, it affects the design of the frame.

I see. So it is possible to create a more minimalist design.

The thickness of the bridge is reduced, and the bridge is made in the same delicate manner. However, this alone is not strong enough to cover the bridge, so it is double-layered in the front and back to cover the bridge.

Nakagawa: Normally, the thickness of the wick and the bridge should be set about the same. . Therefore, we were able to create a very delicate and slender design. Actually, the frame is also made of titanium, so it is flexible and covers the problem of strength.

Are there any other unique parts besides screws?

Pearl oysters are a material used for clothing buttons. These pads are made at a button factory in Nara, Japan.

Nakagawa:The part of the pad that touches the nose is made of mother-of-pearl. They are actually very comfortable to use, and are very fine. . There is only one disadvantage: it is made of calcium, so it wears out as you use it. If we were making a tool that was easy to use and would not break, we would attach chemical fiber to this part, but we chose something that is comfortable to use, sticking to the theme of "a beautiful tool.

Because he applied for a patent, he also created a special tool at the same time. In addition to being available at wholesale locations, they are also available for sale so that customers can maintain them themselves.

What do I do after it wears off?

Nakagawa: We are trying to make it replaceable. This whole pad can be removed. We have patented that clasp.

. This item looks like it has no frame.

Like fashion, eyewear is released twice a year, but for "10 eyevan," Nakagawa says, "When we have something good, we release it. Nakagawa says, "We release new products when they are good.

Nakagawa:That's right. . The U-shaped wick is designed to hold the lens in place from the front and back. The wick slides to match the thickness of the lens, making it possible to accommodate glasses of any power. . This design is also made possible by the Torx screw.

. Thorough attention to detail is paid in order to realize the particulars.

I see that you have added celluloid frames to the "10 Ivan" lineup this time around.

Clockwise from top left: No.3III, No.5III, No.3III, No.7III, No.3III, No.7III, ¥58,000+TAX each

10 eyevan〉No.5III COL.1005S ¥58,000+TAX

10 eyevan〉No.5III COL.1001S ¥58,000+TAX

10 eyevan〉No.7III COL.1000S ¥58,000+TAX / CLIP ¥28,000+TAX

Nakagawa:That's right. I had originally wanted to do plastic frames for "10 Ivan," but it was difficult to find good dead stock fabric.

You are also particular about the fabrics you use.

Nakagawa:You may have often heard of celluloid frames, but most of the fabrics in circulation today are made of acetate. Celluloid is the world's oldest plastic, created by the British in about 1850, and is made from nitrocellulose and camphor, both of which are derived from plants. Both are derived from plants, so they are naturally derived and return to the soil, and they are very fine and pleasant to the touch. If we were to use clothing fiber as an analogy, it would be like silk.

The board in the photo is about a piece of eyewear. This time, dozens of dead stock boards as large as a tatami mat were found.

Why is acetate mainstream now?

Nakagawa: This is because nitrocellulose is difficult to handle. . It is a material for gunpowder. It is difficult to handle in factories because sparks and other things can cause fires. That's why they switched to acetate. Celluloid is still being made in a very limited number of factories, but it has to be laid down after production in order to stabilize quality. So we were waiting to find a good fabric.

So you found a satisfactory dead stock fabric this time.

Nakagawa: Yes, I kept talking to various people and finally found it.

What were you conscious of when it came to design?

Nakagawa: Screws and pearl oyster pads are also used here. Also, the hinges are also a key point. Usually, alloy hinges are used for plastic frames, but they are incompatible with beta-titanium.

Is it because they are different in intensity?

Nakagawa:That's right. That is why we also made these fine hinges out of titanium. This is why even celluloid frames have a smooth "wriggle" action. In this way, we not only use dead stock celluloid, but also pay attention to the smallest details.

If we don't try new things, our technology will become old.

You mentioned earlier that you have created an environment that allows you to realize your ideas. I think most of the production process of "10 Ivan" is made in Sabae City, Fukui Prefecture, and Sabae is famous for its division of labor when it comes to eyeglasses. Does that mean that there were specialists and craftsmen in each part making and production process?

Nakagawa: Yes, that's right. Although there is a division of labor, the rough system is that there is a main manufacturer that coordinates production, and orders for parts are placed to the various factories from there. However, what we did this time was to contact each parts factory directly.

So you moved your feet.

Nakagawa:When we consulted with manufacturers about making a shell pad, they would just say, "That's impossible," and that would be the end of it. It would be inefficient to go to the trouble of doing such a thing just for the sake of the bureaucracy. However, if we reverse the concept, we can make the parts and ask them to use them, and they will do it. We have been in the eyewear industry for a long time, including retail sales. That track record also gave us a boost.

Nakagawa says, "What I think is cool has a good reason. Nakagawa says that he is attracted to details and designs that are necessary, like military wear. In a sense, "10 Ivan" is created with the same sense.

What was the reaction of the craftsmen when you were making the parts?

Nakagawa:They generally didn't like me (laughs). (Laughs.) If we failed, we would end up with defective products, so they would recommend methods that had already been proven in the past. But I repeatedly explained to them that this is what we wanted to do. Since I had known them for a long time, they understood my character, and they finally agreed to do it. But the craftsmen seemed to be enjoying the challenge more and more. If this is successful, the factory will be able to improve its techniques and apply them to other jobs. . There is a concern that if we don't try new things, our techniques will become outdated and we won't get any more orders. In that sense, I told them that they should definitely do it.

We do not end with the creation of a model, but rather, we cherish each and every one of our models.

What do you want customers to take away from 10 Ivan?

Nakagawa: "10 Ivan" is not an eyewear that makes a big impact visually. . However, when you actually try it, you will realize the difference from what you are used to. In fact, I have been wearing celluloid frames for about a month now, and I feel the comfort of natural materials and the ease of use that only modern technology can provide. I would like people to know the difference between celluloid frames and conventional eyewear.

Lastly, what are your goals for "10 Ivan" in the future?

Nakagawa:Old-established shoe manufacturers still have many wooden patterns, which are used to make shoes. This is something we have been thinking about since our establishment, and we at "10 Ivan" would like to do the same thing and cherish each and every model, rather than just making a pair of shoes and calling it a day. For example, we would like to make the same model in different materials, or rearrange the design to create a new model, and in this way we would like to gradually expand what we want to do. We are not so eager to do something that we can't do it by any means. We just go at our own pace. That is the direction 10 Ivan is aiming for. There is common sense in every industry, but what 10 Ivan has done is to step outside of that common sense and create a new framework. However, I believe that we were able to achieve this because of our experience and accomplishments.

The celluloid eyewear mentioned in this story will go on pre-sale at the "Ivan 7285 Flagship Stores" in Osaka and Tokyo on December 7 (Sat). At "Ivan 7285 Tokyo" located on Kotto Dori in Aoyama, Mr. Nakagawa will be in the store to serve customers on December 7 and 8, the two days of the pre-sale. Please visit the store and enjoy the difference from conventional eyewear.

Photo_Shinji Serizawa

Text_Yuichiro Tsuji

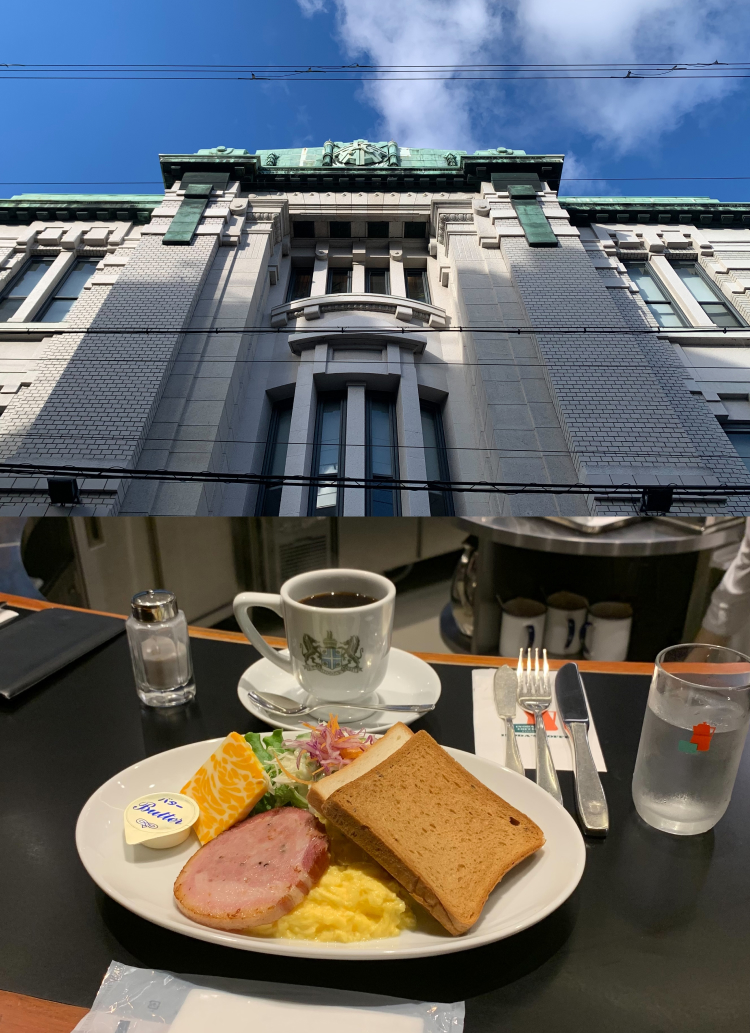

EYEVAN 7285 TOKYO

Address: 5-16-2 Minami-Aoyama, Minato-ku, Tokyo

Phone: 03-3409-7285

Hours: 11:00 - 20:00 (closed Tuesdays)

http://10eyevan.com