Designers talk about Beloof Baggage and Toyooka Bag.

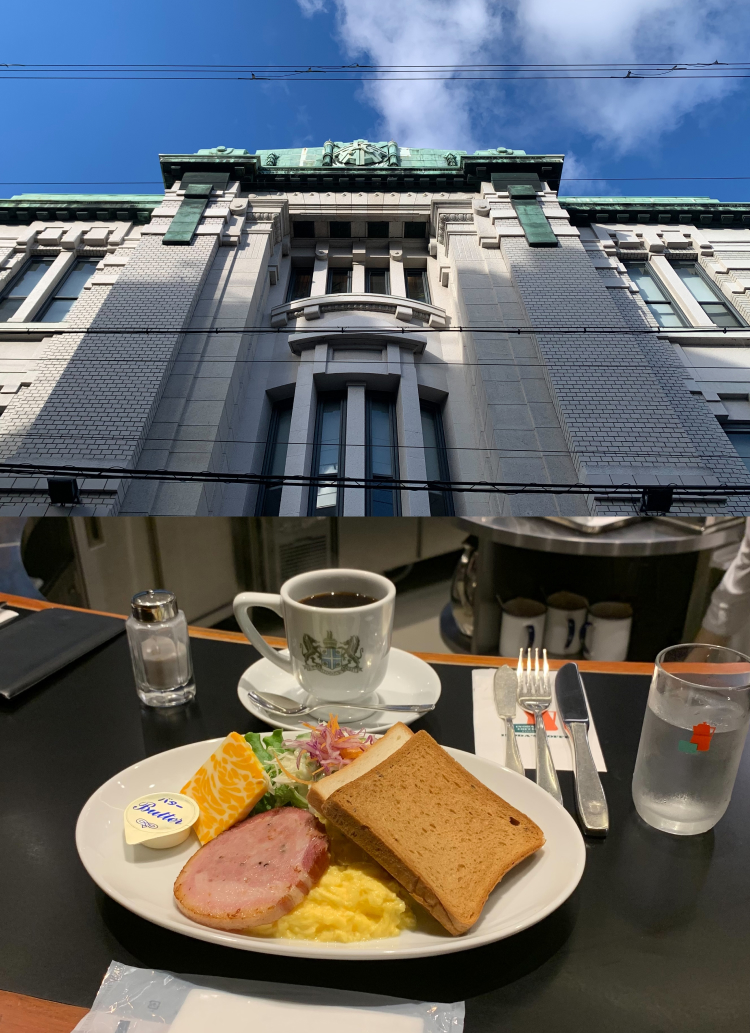

Masaaki Kiwada Shoten is a company that Mr. Sano of places great trust in. When one imagines a bag production site, one tends to imagine a mechanical production method where everything is automated, but it is clear that quality is maintained down to the smallest detail and made with care through the skillful manipulation of machines by people.

It is a common saying that "God is in the details," and it is no exaggeration to say that products from BELF BAGGAGE and TOYOOKA BAGGAGE, both of which have many small parts, are the ones where the true value of this saying can be felt. We asked Mr. Sano to talk about the appeal of these collaborative items.

Please tell us about the concept behind the design of the "Urban Commuter" series.

Sano:The lineup is designed for the business scene. The basic premise of the design is that the bags can be used even by those who wear suits. However, it is not a stereotypical business bag, and it is not a typical work bag that can be used by people in jackets without discomfort, or even for off-duty use.

From left to right, "2×3WAY BRIEF PACK HA" ¥49,000+ TAX, "2WAY BACK PACK HA" ¥27,000+ TAX, "2WAY TOTE BAG 2 HA" ¥34,000+ TAX, "BACK PACK 2 HA" ¥36,000+ TAX TAX

Sano:The fabric is ballistic nylon woven with Cordura yarn, which is hollow inside. This is why it is so lightweight. Of course, the bag is water-resistant and has pockets in places that are easy to reach when the bag is carried on the back, which are bicycle-derived features that BELF BAGGAGE has always excelled at.

I understand that you are also releasing a new travel series.

Sano:Yes, it is. The fabric is the same as that of "Urban Commuter". This series features a solid design. I don't place pockets in positions that would be my blind spots. There are many pickpockets abroad, and even if you walk around with a normal bag on your back, I think you are unconsciously carrying stress. I designed this series to alleviate such feelings as much as possible.

Also, if there are too many pockets, it is easy to lose track of where you put your luggage, so we have created pockets and computer compartments in the main compartment so that you can sort your luggage into these compartments. This is true of all BELF BAGGAGE items, but we are conscious of creating a space that allows the user's imagination to run wild.

Q. Why did you decide to release these items in collaboration with "Toyooka Bag"?

Sano:We originally had our in-line items made at Masaaki Kiwada Shoten. This factory has a wide range of items that can be made, and they are able to achieve a very high grade of quality. Of course, I knew that many of Toyooka Bag's items are made here, and I wanted to introduce each brand to each other's fan base through collaboration.

I was expecting to see more mechanical processes, but I got the impression that it was very analog, with detailed cutting of parts, sewing them one by one, and careful processing of the leather.

Sano:That's right. I have also realized something while visiting factories several times. Even when handling machines, the tension applied to the fabric varies depending on the product to be made. The way the machine is handled also changes accordingly. We have a very good balance between relying on machines and adding human hands.

Sano:And in terms of quality, I feel very secure. With a division of labor system, if there is a slight oversight in the process of passing the product from one person to another, that alone can result in a big loss. But with our integrated production system, corrections can be made immediately.

You said that this factory has a lot of attractions.

Sano:That's really true. I make a drawing of the design in my mind and draw a pattern from there, but at the sample-making stage, the craftsman in charge of sewing says to me before sewing, "If you don't do it this way, it won't have a beautiful form. The craftsman in charge of sewing would say before sewing, "If you don't do it this way, it won't have a beautiful form," and he would give me precise advice on how I should do it. The beautiful form of these bags is also made possible only by Masaaki Kiwada Shoten.

Lastly, please tell us about your future plans for Beluf Baggage.

Sano:The apparel industry basically has an exhibition once every six months, but we think we don't need to be conscious of that routine. We don't want to create new models for that, but rather we want to create them when we can. When our lifestyle changes, we may need a new bag, and I think there are many ideas latent in the unconscious actions we take in our daily lives. We need to be sensitive to such changes. I would like to continue to make good bags with this awareness in mind.