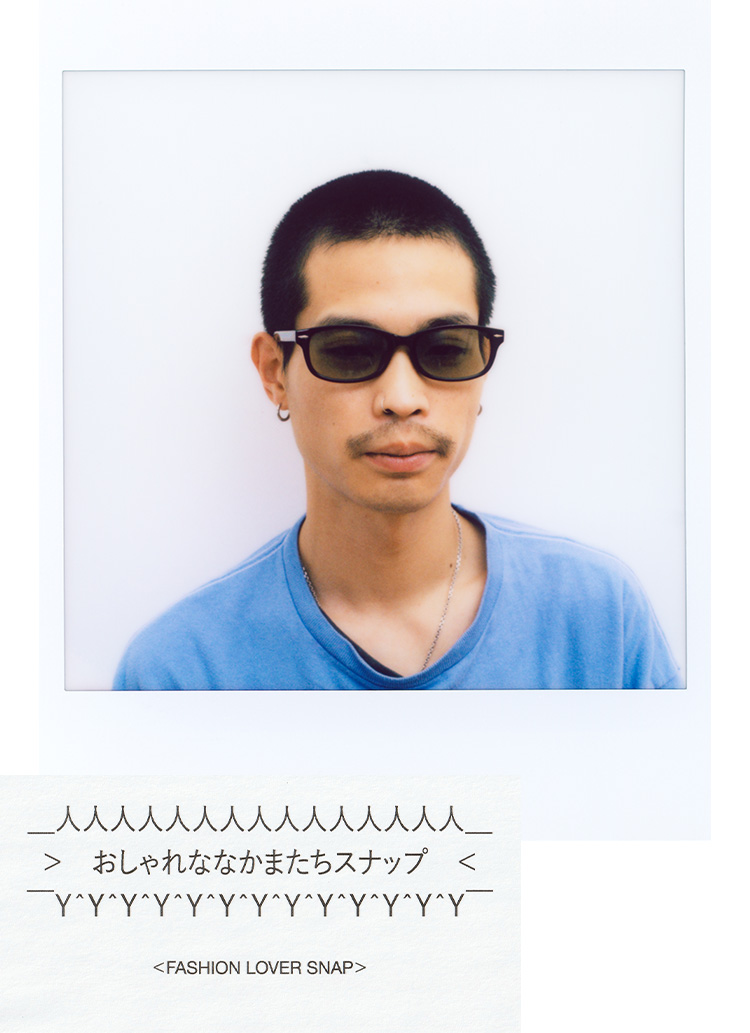

PROFILE

Born in Miyagi Prefecture, he has been working at BAYCREW'S in PR and buying in addition to his duties at Red Wing since 2020.

Instagram: @as71022

We want to put boots in the hands of our customers at a fair price.

Please tell us what the "UPCYCLE PROJECT" is all about.

Abe:Red Wing has been manufacturing unchanged since the company's founding and has stubbornly adhered to its old-fashioned manufacturing methods for a long time. The shoes are made in a way that they can be repaired and worn over and over again. This project was started based on this premise. We revive worn-out boots and add new value to them. In this way, we started this project to convey the inherent sustainability of Red Wing to everyone.

Since the pandemic occurred in 2020, the capacity utilization rate of our factories in the U.S. has dropped significantly. As a result, of the 80 products originally produced, only 9 are now being manufactured. Moreover, the supply is not yet stable. We have heard that boots are being sold at a premium in some parts of the world. We do not approve of such a situation, and we want our customers to be able to use their Red Wing boots for a long time, and we also want to provide our boots to our customers at a fair price.

The pandemic has made it impossible for craftsmen to work in the factories.

Abe:Yes, we do. We are short of human resources. The same situation applies to the parts factories and other facilities involved in this project, and the supply of parts has not kept pace, so the 100% is still far from being ready for operation.

That's why you want people to repair and wear items that have been sitting in their shoe boxes, instead of buying new boots that are more expensive on the secondary market.

Abe:We hope that those who originally owned the boots will do so. Shoe repair shops are very happy to receive Red Wing work boots. This is because the structure is very easy to repair and the quality is easy to guarantee. This project is rooted in our desire to reintroduce the appeal of these boots.